Tech

How to Enable/Disable Exchange ActiveSync?

Exchange ActiveSync is a client protocol developed by Microsoft. It is used to connect and sync mobile devices with mailboxes on Exchange Server. ActiveSync allows Outlook users to access their mailbox items, such as emails, contacts, attachments, calendar, tasks, etc. from their smartphones securely. The Exchange synchronization protocol works with both high latency and low bandwidth networks, which allows users to access their emails even when the network strength in their mobile device is weak.

ActiveSync is enabled by default in Exchange for new users. However, you can enable or disable ActiveSync for users to allow or prevent them from accessing or synchronizing their Exchange mailbox on mobile devices.

Exchange administrators can enable or disable ActiveSync access by using Exchange Admin Center (EAC) or Exchange Management Shell (EMS). In this guide, we will discuss steps to enable or disable ActiveSync in Exchange using both EAC and EMS.

Steps to Enable or Disable Exchange ActiveSync

Follow these steps to enable or disable the ActiveSync protocol in Exchange Server 2010 SP1 and later versions via Exchange Management Shell (EMS). You can also use the Exchange Admin Center or EAC in Exchange 2013 or later versions to control ActiveSync and other aspects, such as,

- Enable or disable ActiveSync for specific users

- Remote wipe data from lost or stolen mobile devices to prevent unauthorized access to company’s sensitive information

- Export user mail items into multiple formats

- Set or change security policies, such as password length, complexity, attempts, etc.

Assign the Roles and Permissions

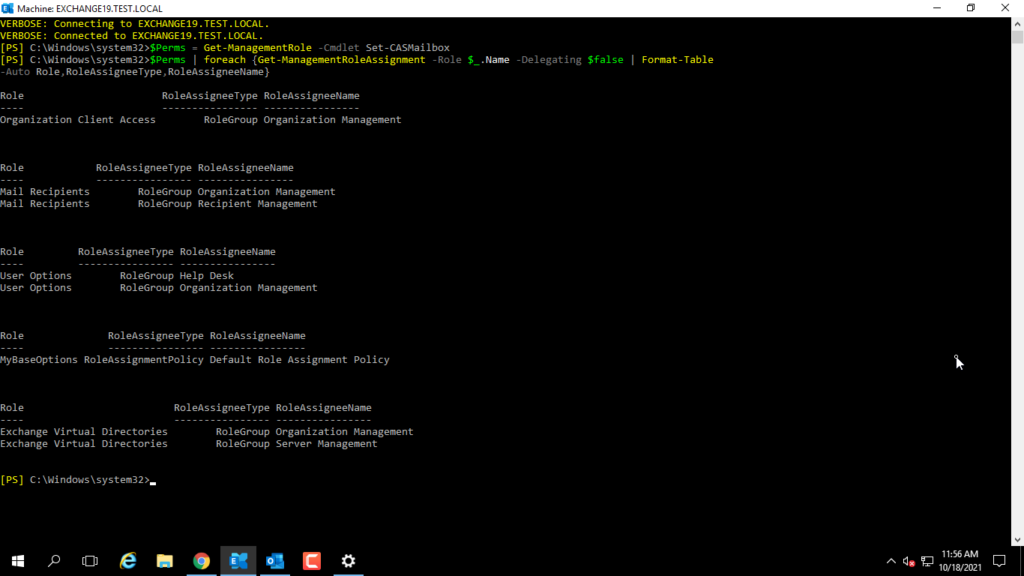

You can check the permission and roles required to enable or disable Exchange ActiveSync by executing the following commands in the Exchange Management Shell.

$Perms = Get-ManagementRole -Cmdlet Set-CASMailbox

$Perms | for each {Get-ManagementRoleAssignment -Role $_.Name -Delegating $false | Format-Table -Auto Role, Role Assignee Type, Role Assignee Name}

You can verify if the “Organization Client Access” role is already assigned to your user account by running the following command in EMS,

Get-ManagementRoleAssignment -Role “<RoleName>”

For instance,

Get-ManagementRoleAssignment -Role “Organization Client Access”

If not, you can assign these roles and permission by using the Exchange Admin Center or Exchange Management Shell (EMS).

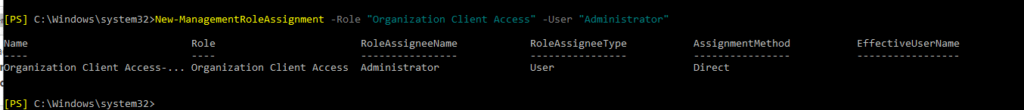

In EMS, execute the following command to assign the role required to enable or disable Exchange ActiveSync.

New-ManagementRoleAssignment -Role “<RoleName>” -User “<UserName>”

Replace <RoleName> with the required role name and <UserName> with the username of your account you are using to enable or disable Exchange ActiveSync. For instance,

New-ManagementRoleAssignment -Role “Organization Client Access” -User “Administrator”

After the role is assigned, you can go ahead and follow the steps

Enable or Disable ActiveSync via Exchange Admin center

The steps are as follow,

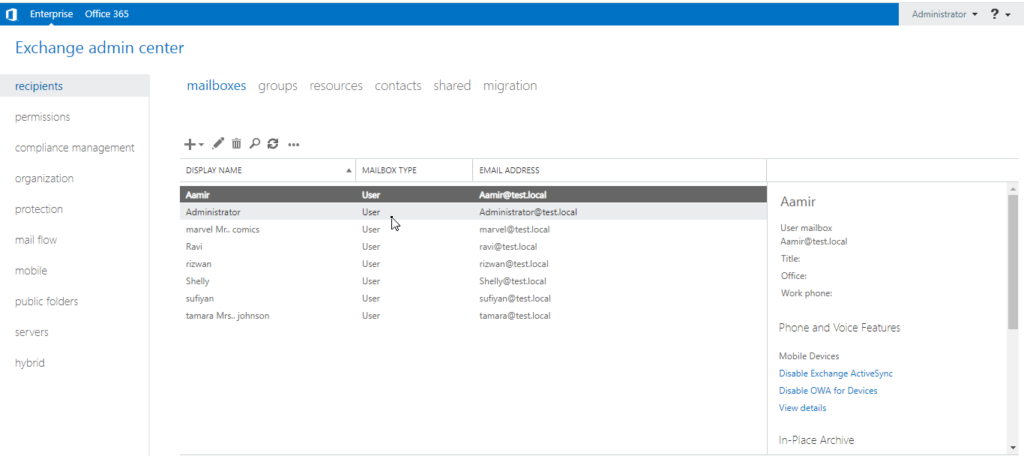

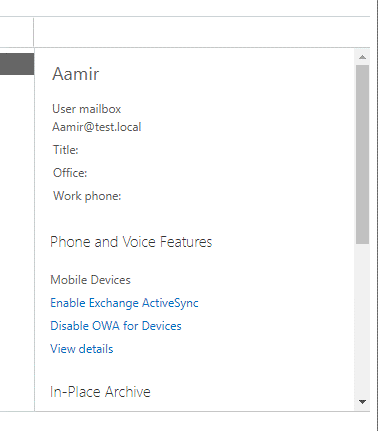

- Open EAC and navigate to recipients> mailboxes.

- Select user mailboxes for which you want to disable the ActiveSync.

- On the right-pane, click ‘Disable Exchange ActiveSync.’

- Click ‘Yes’ to confirm.

- The Exchange ActiveSync service will be disabled for the particular user mailbox.

To enable the Exchange ActiveSync for user mailbox, follow these steps,

- Select the mailbox in recipient> mailboxes.

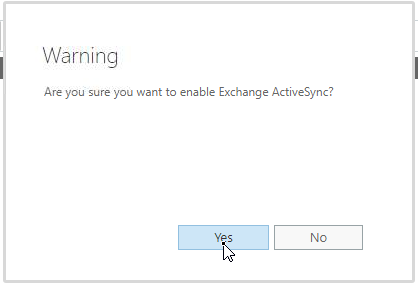

- Click ‘Enable Exchange ActiveSync’

Click ‘Yes’ to confirm

- This will enable the Exchange ActiveSync service for the specific user.

Enable or Disable ActiveSync via Exchange Management Shell (EMS)

The steps are as follow,

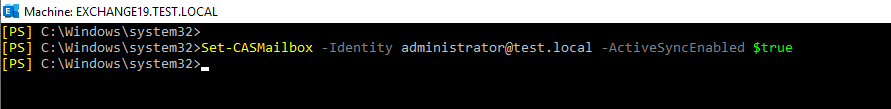

- Open Exchange Management Shell (EMS) as administrator and run following command,

Set-CASMailbox -Identity <SMTP Address of user> -ActiveSyncEnabled $true

For instance,

Set-CASMailbox -Identity administrator@test.local -ActiveSyncEnabled $true

- This will enable the ActiveSync services for the particular Exchange mailbox.

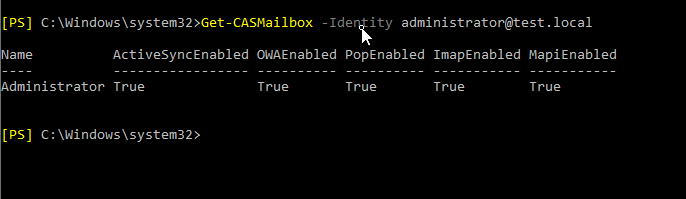

- You can then execute following command to check if ActiveSync is enabled for the user

Get-CASMailbox –identity <SMTPAddressOfUser>

For instance,

Get-CASMailbox –identity administrator@test.local

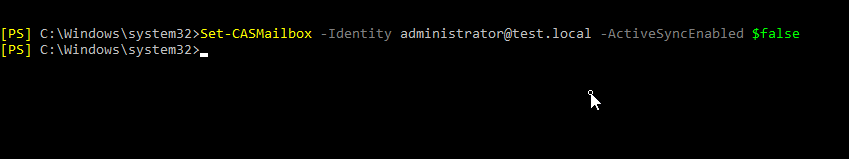

Disable Exchange ActiveSync via EMS

The steps are as follow,

- Open EMS as administrator and run following command to disable ActiveSync for particular user,

Set-CASMailbox -Identity administrator@test.local -ActiveSyncEnabled $false

- Check the ActiveSync status for particular user by running following command,

Get-CASMailbox –identity administrator@test.local

To Wrap Up

When Exchange ActiveSync is enabled, employees or users can access their mailboxes from both PC and mobile devices. In Exchange Server 2010 and later, the ActiveSync is enabled by default for new users. However, as an Exchange administrator, you may require to enable or disable Exchange ActiveSync for users facing issues with their mailboxes. Sometimes, users may encounter issues with Exchange ActiveSync enabled profiles when their mailbox gets larger or reaches a certain size limit. In such cases, you can use an EDB to PST converter tool, such as Stellar Converter for EDB, to export the mailboxes or mail items to a new database or mailbox.

Business

The Importance of Local SEO 2025: Boosting Visibility & Driving Growth

In present hyper-connected world, simply having a website isn’t enough—local visibility is everything. Whether you’re running a coffee shop in Bristol or offering plumbing services in Chicago, your ability to show up in local search results can make or break your business. That’s where Local SEO steps in.

As of 2025, over 78% of location-based searches on mobile lead to an offline purchase, proving that consumers are searching locally with the intent to act quickly. For small businesses, local SEO is no longer a luxury—it’s a necessity for growth, trust, and survival in a competitive digital landscape.

What Is Local SEO?

Local SEO (Search Engine Optimization) is a digital marketing strategy focused on improving a business’s visibility in geographically-related search results, particularly on Google. Unlike traditional SEO, which targets a global or national audience, local SEO helps your business rank when users search for services “near me” or include a specific city, town, or neighborhood in their query.

In 2025, local SEO revolves around optimizing your Google Business Profile, ensuring NAP (Name, Address, Phone Number) consistency across directories, earning positive reviews, and using geo-targeted keywords. With over 46% of all Google searches now having local intent, local SEO is essential for attracting nearby customers, increasing foot traffic, and building trust in your local community.

Whether you run a bakery in Manchester or a law firm in Brooklyn, local SEO ensures you’re found when it matters most—right in your customer’s neighborhood.

Why Local SEO Is Important?

In 2025, local SEO is more vital than ever, as consumer behavior shifts towards hyper-local, instant search experiences. Here’s why it matters—and what the latest data reveals:

1. Rise of “Near Me” Searches

Searches containing “near me” have grown by more than 150% in the past two years, according to Google Trends. People now expect instant, localized results. Local SEO ensures your business ranks for these intent-driven searches, allowing you to capture nearby users looking for products or services they need immediately, increasing leads, calls, and walk-in visits dramatically.

2. Mobile Search Dominance

As of 2025, over 65% of local searches come from smartphones. Consumers use mobile to find local businesses, check reviews, get directions, and contact services on the go. Local SEO helps ensure your business is fully optimized for mobile results, improving your Google Maps placement and capturing high-intent users who are ready to act quickly after finding your business.

3. High Purchase Intent of Local Searches

Local SEO targets users with strong purchase intent. Research from BrightLocal reveals that 78% of local mobile searches result in a purchase or store visit within 24 hours. By showing up in relevant local searches, your business connects directly with ready-to-buy customers—making local SEO one of the highest ROI strategies for small and location-based businesses in 2025.

4. Voice Search Growth in Local Discovery

Voice assistants like Siri, Alexa, and Google Assistant are transforming local search. As of 2025, 58% of users rely on voice search to find local businesses. Queries like “best pizza place near me” or “24-hour vet nearby” are common. Local SEO ensures your business is voice-friendly, increasing discoverability for location-based, conversational search queries used daily on smart devices.

5. Google Maps as a Primary Discovery Tool

Google Maps has become the default tool for finding local businesses. In 2025, over 84% of users turn to Maps for directions, hours, or reviews. Without local SEO—especially a well-optimized Google Business Profile—your business may not appear at all. Proper optimization ensures you’re visible in local packs and map results where purchasing decisions happen in real time.

6. Impact of Reviews on Local SEO Rankings

Customer reviews are a major ranking signal in Google’s local algorithm. According to Whitespark’s 2025 report, reviews influence 16% of local pack rankings. High ratings, review frequency, and owner responses increase credibility and boost visibility. A strong local SEO strategy includes review generation and response management, helping businesses build trust and gain better placement in search results.

7. Local SEO Builds Brand Trust and Authority

Local SEO helps establish your business as a trustworthy local authority. A BrightLocal study shows 87% of users read reviews before engaging with a business. Verified listings, accurate contact details, quality content, and consistent branding across directories all contribute to higher trust and user confidence—crucial for conversions and long-term customer relationships in your local market.

Benefits of Local SEO

1. Increased Visibility in Local Search Results

Local SEO boosts your presence on Google Maps and in the “Local Pack,” which appears above organic listings. In 2025, over 84% of users click on local results when searching for nearby services. By optimizing your Google Business Profile and local keywords, your business appears where customers are looking—right in your service area.

2. More Foot Traffic and Local Engagement

Optimizing for local SEO drives real-world results. Google data shows 76% of users who conduct a local search visit a business within 24 hours. Accurate location info, mobile-friendly sites, and map listings guide customers directly to your storefront, significantly increasing in-store visits and personal engagement with high-intent local shoppers and clients.

3. Higher Conversion Rates from Local Searchers

Local searchers have strong intent to buy. According to BrightLocal, 78% of location-based searches result in purchases. Local SEO positions your business in front of customers who are actively seeking what you offer. This leads to faster conversions, higher-quality leads, and better ROI compared to untargeted traffic from generic or broad keyword campaigns.

4. Improved Online Reputation and Trust

Reviews are essential in local SEO. A 2025 ReviewTrackers study shows that 87% of consumers won’t consider a business with low ratings. Local SEO includes review management and response strategies, which enhance trust, increase credibility, and influence decision-making—leading to more clicks, bookings, and sales from new and returning customers.

5. Competitive Advantage Over Local Rivals

Many small businesses still overlook local SEO, giving you a chance to stand out. By optimizing your listings, content, and citations, you can outrank nearby competitors in search results. This improved visibility helps attract more customers in your area, even if competitors offer similar products or services but lack strong digital presence.

6. Cost-Effective Marketing Strategy

Local SEO provides long-term, sustainable exposure without the ongoing costs of ads. Once optimized, your listings and rankings continue to drive organic traffic. In 2025, small businesses using local SEO report 60% lower cost per acquisition compared to paid ads. It’s one of the most efficient ways to grow locally without draining your budget.

7. Boosts Local Brand Awareness

Appearing in multiple local searches helps reinforce your brand name and presence within your community. Whether someone sees your business on Google, a directory, or in reviews, repeated exposure builds recognition. Local SEO ensures your brand shows up consistently in all local digital touchpoints, making your business top-of-mind for nearby consumers.

How Local SEO Works?

Local SEO works by optimizing your online presence so that search engines—especially Google—understand your business’s location, services, and relevance to local searchers. It helps your business appear in key places like Google’s Local Pack, Google Maps, and localized organic search results when people search for nearby solutions.

How Local SEO works?

1. Google Business Profile Optimization

Claiming and optimizing your Google Business Profile (GBP) is the foundation. You must ensure your address, phone number, business hours, categories, and photos are accurate and up to date. According to a 2025 Whitespark study, GBP signals are the #1 ranking factor for Google’s Local Pack results.

2. NAP Consistency Across Listings

Search engines scan business directories (like Yelp, Facebook, Bing Places) to verify your Name, Address, and Phone Number (NAP). Consistency builds trust. Inconsistencies can confuse Google and lower your rankings. Tools like Moz Local and BrightLocal help automate and audit citation consistency across the web.

3. Local Keyword Targeting

Local SEO involves targeting geo-specific keywords like “best Italian restaurant in Glasgow” or “emergency plumber near me.” You integrate these keywords into your website pages, blog posts, meta tags, and headings to signal to Google that you’re a relevant match for local intent searches.

4. Online Reviews and Ratings

Customer reviews, especially on Google, directly influence your rankings. Positive reviews improve click-through rates and trust. Responding to reviews is equally important—it signals engagement and reliability. In 2025, reviews account for over 16% of local search ranking factors (Whitespark).

5. Local Backlinks and Citations

Backlinks from local websites, news sites, or blogs strengthen your local authority. Additionally, local citations (mentions of your business name and details) across trusted directories reinforce your legitimacy and boost visibility in Google’s local search algorithm.

6. Mobile and Voice Search Optimization

With over 65% of local searches coming from mobile devices and 58% from voice assistants in 2025, your website must be mobile-friendly, fast-loading, and structured with clear answers to conversational queries (e.g., “Where’s the nearest vet clinic open now?”).

7. Location-Based Content

Creating content that speaks directly to your community—like neighborhood pages, local blogs, or city-specific landing pages—helps you rank higher in local results. This tells Google that your site is relevant not just to what users are searching, but where they’re searching from.

How to Do Local SEO?

1. Claim and Optimize Your Google Business Profile

Start by claiming your Google Business Profile (GBP) through Google’s official platform. Fill out every detail including your business name, address, phone number, category, working hours, and website URL. Upload high-quality images and videos, post regular updates, and respond to customer questions. In 2025, fully optimized profiles are 7x more likely to get clicks and 70% more likely to lead to in-store visits compared to incomplete listings.

2. Ensure NAP Consistency Across All Platforms

NAP stands for Name, Address, and Phone number—and consistency is critical across your website, local directories, and social platforms. Inconsistent contact information confuses both users and Google’s algorithm, lowering your local ranking potential. Use tools like Moz Local or BrightLocal to audit and fix discrepancies. Accurate citations help Google trust your business and boost your visibility in local search results.

3. Target Local Keywords Strategically

Local SEO relies heavily on geo-targeted keywords such as “best bakery in Bristol” or “24-hour locksmith near me.” Use SEO tools like Google Keyword Planner or Semrush to research high-intent local phrases. Integrate these keywords naturally into your website content, service pages, meta descriptions, and your Google Business Profile. This improves your chances of ranking for location-specific queries made by nearby customers.

4. Get Listed in Trusted Local Directories

Submitting your business to high-authority local directories like Yelp, Bing Places, Foursquare, Yellow Pages, and Facebook boosts your visibility. These listings act as digital citations and help build local authority. Make sure all listings match your NAP format exactly and include categories, services, and links to your website for better ranking in Google’s local pack and Maps results.

5. Collect and Manage Online Reviews

Online reviews are a powerful ranking and trust factor. Encourage satisfied customers to leave Google reviews, and actively respond to feedback, both positive and negative. In 2025, businesses with over 50 recent reviews enjoy significantly higher visibility. Reviews not only build credibility but also influence consumer decisions, so monitor and manage them through tools like ReviewTrackers or Google’s review dashboard.

6. Optimize Your Website for Local SEO

Your website should clearly reflect your business’s location and offerings. Create location-specific landing pages, use local schema markup, embed Google Maps, and include your full NAP on every page. Ensure your site is mobile-friendly and loads fast, as 65% of local searches come from mobile devices. Google prioritizes user experience, especially for local intent searches.

7. Build Local Backlinks and Earn Citations

Earning backlinks from local sources like news sites, blogs, schools, and community pages improves your local SEO authority. Participate in or sponsor local events to get mentioned in regional publications. Also, increase your citations—mentions of your business details without links—on trustworthy directories. These signals help Google verify your physical presence in the area and improve your ranking.

8. Create Hyperlocal and Relevant Content

Publishing local content builds relevance with your community and search engines. Write blog posts about area-specific challenges, local events, customer stories, or “how-to” guides related to your services in your city. This positions your business as an active, relevant local resource while helping your site rank for long-tail, location-specific queries that drive qualified traffic.

9. Use Dedicated Location Pages for Multiple Branches

If your business operates in more than one area, create unique landing pages for each location. Include localized content, reviews, maps, and service details. Avoid duplicate content—tailor each page to reflect the community it serves. Adding schema markup and localized keywords ensures each location ranks individually and accurately in the relevant city or neighborhood.

10. Track, Analyze, and Improve with Local SEO Tools

Use tools like Google Search Console and Google Analytics 4 to track your local traffic, user behavior, and conversions. Platforms like BrightLocal, Whitespark, or Semrush Local offer advanced tracking for rankings, citations, reviews, and competitor analysis. Regularly auditing and updating your local SEO efforts helps you adapt to algorithm changes and maintain long-term visibility.

Top Local SEO Tools & Resources

1. Google Business Profile Manager

Google Business Profile (GBP) Manager is the backbone of local SEO. According to Google, listings with complete profiles receive 7x more clicks and 70% more direction requests than incomplete ones. In 2025, GBP directly influences visibility in the Local Pack, which now accounts for 42% of all local clicks. Posting updates, replying to reviews, and using GBP insights help improve real-world footfall and search rankings.

2. BrightLocal

BrightLocal is used by over 80,000 agencies and local businesses to manage citations, monitor reviews, and track local rankings. Its Local Search Grid feature provides visual insight into how your business ranks in specific areas. A 2025 survey shows that businesses using BrightLocal see an average increase of 32% in local keyword visibility within 3 months of consistent optimization efforts.

3. Moz Local

Moz Local automates listing management across dozens of directories, helping businesses maintain accurate NAP data. In 2025, Moz’s citation sync reduces manual errors by over 90% and improves local search stability across platforms like Yelp, Apple Maps, and Bing. A Moz study shows that businesses with consistent NAP data experience 28% better ranking outcomes in Google’s Local Pack.

4. Semrush Local SEO Toolkit

Semrush’s Local SEO Toolkit is integrated into its broader SEO suite, used by 10 million marketers globally. In 2025, its AI-driven auditing and geo-targeted trackingwill provide up to 96% keyword accuracy for local ranking data. A recent case study showed that small businesses using Semrush’s local features improved local organic traffic by 40% within 60 days.

5. Whitespark

Whitespark’s Local Citation Finder helps businesses uncover directories and platforms that competitors are listed on, but they are not. In 2025, Whitespark clients reported a 24% improvement in local search rankings after citation cleanup and discovery campaigns. It also offers Google Review Link Generators, making it easier to get customer reviews—a key local ranking factor.

6. Yext

Yext manages your business data across more than 200 platforms, including Amazon Alexa, Apple Maps, Facebook, and Waze. Research from Yext shows that consistent data across listings improves search engine trust signals by over 35%, which directly affects Local Pack rankings. It’s ideal for multi-location businesses that require high-scale automation and brand control.

7. ReviewTrackers

In 2025, 93% of consumers say online reviews influence buying decisions (Source: ReviewTrackers). This tool allows businesses to monitor, collect, and respond to reviews from Google, Facebook, Yelp, and more—all from one dashboard. Sentiment analysis and competitor benchmarks help brands improve their reputation and boost click-through rates by up to 25% in local search results.

8. Local Falcon

Local Falcon maps your Google Business Profile ranking position across a grid of search points in a specific area. This reveals your real-world local SEO coverage radius, which is increasingly important in 2025’s proximity-based algorithm. Businesses using Local Falcon typically discover 15–30% of their service areas are underperforming, allowing them to optimize hyperlocal visibility more precisely.

Common Mistakes to Avoid in Local SEO

1. Inconsistent NAP (Name, Address, Phone Number) Details

One of the most damaging mistakes in local SEO is having inconsistent business information across directories and platforms. Google relies on consistent NAP data to validate your legitimacy. In 2025, businesses with mismatched citations saw a 22% drop in local rankings (Source: Whitespark). Always ensure your NAP is identical across your website, Google Business Profile, Yelp, and other directories.

2. Neglecting Google Business Profile Optimization

Simply claiming your Google Business Profile isn’t enough. Many businesses forget to update hours, add new photos, or respond to Q&A and reviews. This hurts engagement and visibility. A BrightLocal study shows that optimized profiles receive 5x more views and 3x more actions (calls, clicks, direction requests) compared to inactive or incomplete listings.

3. Ignoring Online Reviews and Reputation Management

Failing to manage reviews—or worse, not generating them—directly affects your local visibility. In 2025, Google confirmed that review quality, quantity, and recency are critical ranking signals. Businesses with fewer than 10 recent reviews rank significantly lower in competitive niches. Actively ask for feedback, reply to every review, and monitor your reputation.

4. Overlooking Mobile Optimization

With over 65% of local searches coming from mobile devices in 2025, having a slow or unresponsive website drives users—and rankings—away. Google prioritizes mobile-first indexing, meaning your mobile experience directly impacts your SEO performance. Ensure your site loads under 3 seconds, is responsive, and features click-to-call buttons and map integrations.

5. Using Generic, Non-Localized Content

Generic content that doesn’t target specific locations fails to rank in local results. Many businesses make the mistake of reusing the same content across city pages or not including local references at all. To rank well, create unique, geo-targeted landing pages with references to neighborhoods, landmarks, or local events relevant to your audience.

6. Keyword Stuffing and Spammy Optimization

Stuffing location names or service keywords excessively in your content or Google Business Profile can backfire. Google’s spam filters in 2025 are more advanced and may flag your listing, reducing visibility or even suspending your profile. Instead, use keywords naturally, prioritizing helpful content that addresses users’ local intent.

7. Not Using Local Structured Data (Schema Markup)

Schema markup helps Google better understand your business’s address, services, and reviews. Many businesses skip this technical step, missing out on rich results like review stars or operating hours in search. In 2025, websites with local business schema had 28% higher click-through rates, according to a study by Schema.org.

8. Failing to Monitor Performance and Analytics

Local SEO isn’t set-and-forget. Failing to track your performance using tools like Google Search Console, GA4, or BrightLocal means missing valuable insights. Regularly reviewing rankings, click-through rates, and user behavior helps identify weak spots and areas to improve. In 2025, top-performing local businesses review and update their SEO strategy at least quarterly.

Conclusion

In 2025, local SEO is no longer optional—it’s essential for small and location-based businesses aiming to grow in competitive markets. From improving visibility in Google Maps to driving foot traffic and building trust through reviews, local SEO delivers real, measurable results.

Apps and Software

Best Work Order Software for Maintenance Efficiency

In present fast-moving industrial and facility environments, maintenance teams can no longer rely on paper-based systems or manual tracking. Work order software has become an essential tool in 2025, enabling businesses to streamline operations, reduce downtime, and optimize asset performance with ease. These digital platforms automate the creation, assignment, and tracking of maintenance tasks—saving time, minimizing errors, and boosting accountability.

With the rise of mobile-first solutions, IoT integrations, and AI-driven scheduling, work order software is now central to achieving maintenance efficiency across manufacturing plants, commercial buildings, utilities, and service sectors. In this guide, we review the 10 best work order software platforms that are redefining maintenance management in 2025.

What Is Work Order Software?

Work order software is a centralized digital platform used to generate, assign, and track maintenance tasks across facilities, equipment, or assets. It simplifies workflows by automating job requests, scheduling preventive maintenance, and maintaining a detailed log of repairs and service history. As of 2025, over 68% of maintenance teams worldwide have adopted work order systems to replace outdated paper-based or spreadsheet tracking methods (Source: Statista Maintenance Tech Trends 2025).

These platforms now feature cloud-based access, mobile integration, AI-driven task prioritization, and IoT connectivity, enabling real-time updates and predictive maintenance. Industries like manufacturing, healthcare, logistics, and utilities rely on this software to cut unplanned downtime by up to 30% and improve asset lifecycle management.

Why Using Of Work Order Software Matter?

1. Reduces Equipment Downtime

Work order software minimizes unplanned equipment failures by enabling timely repairs and preventive maintenance. In 2025, businesses report up to a 40% reduction in downtime, which boosts production output, lowers emergency repair costs, and enhances overall operational efficiency across manufacturing, logistics, and facility management sectors.

2. Improves Preventive Maintenance Compliance

Automated scheduling through work order software ensures preventive maintenance tasks are performed consistently. This results in a 25% improvement in compliance rates and extends asset lifespan, helping organizations avoid reactive repairs, reduce equipment stress, and better adhere to manufacturer service intervals and safety inspection timelines.

3. Centralizes Maintenance Records

Work order software creates a centralized digital repository for maintenance history, parts usage, technician performance, and cost tracking. These records are invaluable for audits, warranty claims, and root cause analysis. It helps teams maintain transparency, regulatory compliance, and better decision-making through accessible and organized maintenance data.

4. Enhances Workforce Accountability

Digital work order assignment allows managers to track technician activity, job status, and time to completion. This improves workforce accountability by identifying inefficiencies and rewarding productivity. Teams work more cohesively with clear expectations, reducing miscommunication and ensuring no maintenance task is overlooked or delayed.

5. Supports Data-Driven Decision Making

Modern work order platforms feature built-in analytics and reporting tools. These insights help managers monitor KPIs, detect recurring issues, and optimize labor and material usage. In 2025, data-driven maintenance strategies can reduce annual maintenance costs by up to 20% across asset-heavy industries like manufacturing and energy.

5 Best Work Order Software in 2025

1. UpKeep

UpKeep is a top-rated, mobile-first work order software designed to streamline maintenance operations and asset management. Trusted by over 4,000+ companies worldwide, it’s known for ease of use, robust mobile access, and fast implementation. In 2025, UpKeep reports that teams using its platform see a 30% increase in technician productivity and 26% fewer equipment failures due to proactive task scheduling.

It supports cloud-based deployment, offline functionality, and integrates with QuickBooks, Slack, and Zapier, making it a go-to for maintenance teams in facilities, manufacturing, and property management sectors.

Key Features:

- Mobile-First Work Order Management: Create, assign, and close work orders from smartphones with real-time updates and offline capabilities for field-based teams.

- Preventive Maintenance Scheduling: Automate recurring tasks with customizable PM templates, reducing reactive maintenance and improving asset reliability over time.

- Asset Management & History Tracking: Link work orders to equipment, track repair logs, and monitor asset lifecycle to support smarter maintenance decisions.

- Inventory & Spare Parts Tracking: Manage inventory levels, receive low stock alerts, and streamline reordering directly from the platform to avoid stockouts.

- In-App Messaging & Collaboration: Communicate directly within work orders to reduce miscommunication and speed up response times across teams and supervisors.

- Analytics & Maintenance Reporting: Gain visibility into key KPIs like mean time to repair (MTTR), technician productivity, and asset performance through interactive dashboards.

Free Plans Include:

- Access for 1 user only

- Unlimited work orders

- Basic asset and location tracking

- Limited reporting and no integrations

- Available on mobile and desktop

Potential Drawback

UpKeep’s lower-tier plans have limited reporting, user restrictions, and no API access, which may not suit larger or highly regulated operations.

Industries Using UpKeep:

- Manufacturing

- Property Management

- Facilities & Building Maintenance

- Hospitality

- Healthcare & Hospitals

- Education Institutions

- Warehousing & Logistics

Best Suited For

UpKeep is best for small to mid-sized teams that need a fast, mobile, and affordable solution to digitize work orders and preventive maintenance. Ideal for businesses with field technicians or distributed assets seeking to boost efficiency with minimal training.

2. Fiix by Rockwell Automation

Fiix is an AI-powered, cloud-based work order and CMMS platform built by Rockwell Automation. Designed for industrial-scale asset management, it simplifies maintenance workflows through smart scheduling, ERP/IoT integrations, and predictive analytics. In 2025, companies using Fiix have seen a 32% decrease in equipment failures and 25% faster task resolution.

Its drag-and-drop calendar, custom dashboards, and mobile app make it a powerful tool for teams managing complex, multi-site maintenance. With open API connectivity, Fiix easily syncs with SAP, Oracle, and SCADA systems, helping enterprises move toward smarter, data-driven maintenance strategies across manufacturing, utilities, and energy sectors.

Key Features:

- AI-Powered Work Order Scheduling: Automates prioritization based on asset health, technician availability, and historical data for smarter maintenance planning.

- Mobile Maintenance Management: Technicians access work orders, checklists, and asset details on the go via the Fiix mobile app—even offline.

- Asset Performance Analytics: Advanced dashboards track equipment health, downtime patterns, and cost analysis to inform smarter capital planning.

- Integration with ERP & IoT Systems: Seamless integration with ERP, SCADA, and condition-monitoring tools enhances workflow automation and real-time alerts.

- Work Order Templates & Escalations: Pre-built templates and escalations streamline task creation and ensure compliance with SLAs or regulatory standards.

Free Plans Include:

- Limited to 3 users

- 25 active work orders/month

- Basic asset tracking & parts management

- Community support only

Potential Drawback

Slight learning curve for non-technical users, and higher-tier features like AI scheduling are available only in premium plans.

Industries Using Fiix:

- Manufacturing

- Food & Beverage

- Energy and Utilities

- Heavy Equipment

- Pharmaceuticals

Best Suited For

Fiix is best suited for large enterprises, manufacturers, utilities, and energy providers seeking predictive maintenance capabilities and full ERP/IoT integration. It’s ideal for businesses with complex compliance needs, large maintenance teams, and multiple facilities that need real-time insights and centralized management.

3. Limble CMMS

Limble CMMS is a cloud-based work order and maintenance platform known for its ease of use, rapid deployment, and strong mobile functionality. It enables preventive maintenance automation, asset tracking, technician performance monitoring, and custom KPI dashboards. As of 2025, businesses using Limble report a 34% increase in task completion speed and 27% drop in reactive maintenance costs.

With QR code integration, multilingual support, and unlimited custom fields, it’s highly adaptable across industries. Limble’s clean UI and responsive customer service make it a top pick for teams wanting a fast, scalable solution that improves visibility, uptime, and maintenance compliance.

Key Features:

- Automated Preventive Maintenance: Set schedules, assign recurring tasks, and reduce emergency breakdowns with flexible PM automation tools.

- Custom Dashboards & KPIs: Configure performance metrics, charts, and goals to match your team’s needs and benchmark asset reliability.

- QR Code-Based Asset Tracking: Scan asset tags to instantly pull up history, work orders, manuals, and parts—reducing search time by up to 40%.

- Multi-Language & Multi-Site Support: Ideal for global teams managing maintenance across multiple buildings and languages.

- Work Request Portal for Staff: Non-maintenance staff can submit and monitor requests without needing a full account or training.

Free Plans Include:

- Free 30-day trial only

- Full feature access during trial

- No long-term free plan

Potential Drawback

Higher-tier pricing may be prohibitive for small businesses; customization options may require onboarding help.

Industries Using Limble:

- Hospitality

- Education

- Healthcare

- Warehousing

- Government Facilities

Best Suited For

Limble is ideal for mid-sized organizations and facility teams in hospitality, education, healthcare, government, and warehousing sectors. It’s especially effective for businesses needing multi-location support, fast onboarding, mobile task management, and strong customer assistance without sacrificing customization or analytics.

4. MaintainX

MaintainX is a mobile-first work order and operations platform designed to simplify maintenance, inspections, and SOP execution. In 2025, it’s trusted by over 10,000 companies, helping them improve communication, compliance, and asset tracking. Teams using MaintainX report a 40% improvement in team coordination due to its built-in chat and real-time update features.

MaintainX supports unlimited work orders (even on free plans), offline mobile use, and document attachment (manuals, checklists, SOPs). It’s especially useful for field service operations, hospitality, retail chains, and multi-site facilities looking to digitize maintenance without overwhelming complexity.

Key Features:

- Unlimited Work Orders: Even on free plans, create and manage unlimited tasks for better responsiveness and operational agility.

- Mobile Chat within Work Orders: Communicate with technicians directly inside task threads—no more switching between apps.

- Digital SOPs & Checklists: Attach standard operating procedures, inspections, or safety protocols directly into work orders.

- Offline Mobile Mode: Field technicians can work without a connection, and changes sync once back online.

- Work History & Compliance Logs: Keep accurate records for audits, safety inspections, and maintenance trend analysis.

Free Plans Include:

- Unlimited work orders & assets

- Up to 5 users

- Access to mobile app, SOPs, and history

- Limited reporting and no integrations

Potential Drawback

Limited functionality in the desktop version; some advanced analytics only available in paid plans.

Industries Using MaintainX:

- Retail Chains

- Hospitality

- Logistics

- Utilities

- Commercial Cleaning

Best Suited For

MaintainX is best suited for retail operations, hospitality groups, logistics companies, and facilities with field-based or mobile teams. It excels in fast-paced environments where real-time communication, compliance checks, and mobile-first execution are critical. Perfect for companies that value simplicity, collaboration, and modern mobile UX.

5. eMaint CMMS by Fluke

eMaint is a robust enterprise-grade CMMS developed by Fluke, offering extensive customization, predictive analytics, and deep compliance features. In 2025, eMaint supports over 50,000 global users and enables a 15–20% reduction in total maintenance spend through its proactive, data-driven features. With multi-site scalability, condition monitoring, and detailed escalation workflows, it serves asset-heavy sectors needing high reliability.

The platform supports ISO compliance, integrates with SCADA and GIS, and provides powerful reporting tools for MTTR, MTTF, and downtime metrics. It’s a premier choice for operations requiring centralized control, advanced planning, and industry-grade safety and audit readiness.

Key Features:

- Condition-Based Maintenance: Triggers work orders from real-time asset data, reducing manual inspections and unplanned breakdowns.

- Multi-Site & Role-Based Access: Enables centralized control over decentralized operations with granular user permissions.

- Work Order Escalation Rules: Automatically escalate overdue or high-priority tasks to ensure quick resolution and accountability.

- Custom Reports & KPIs: Build dashboards to measure MTTR, MTTF, and maintenance backlog trends across teams or assets.

- Integrated Parts & Vendor Management: Streamline procurement workflows with supplier tracking and parts usage history linked to each work order.

Free Plans Include:

- Free demo only

- No long-term free tier

- Custom quote-based pricing

Potential Drawback

Complex to implement; may require extensive training and configuration for non-enterprise users.

Industries Using eMaint:

- Energy & Utilities

- Aviation

- Government Facilities

- Manufacturing

- Pharmaceuticals

Best Suited For

eMaint is best suited for large-scale enterprises, government agencies, aviation, pharmaceuticals, and energy sectors that demand high configurability, audit-compliance, advanced analytics, and integration with industrial systems. It’s ideal for organizations prioritizing long-term asset optimization, failure prediction, and enterprise-wide maintenance visibility.

Benefits of Using Work Order Software

1. Streamlined Maintenance Scheduling

Work order software automates recurring maintenance and task prioritization. In 2025, companies using automated scheduling report a 28% reduction in maintenance planning time. This ensures high-priority tasks are never missed, improving team coordination and minimizing costly unplanned downtime across operations.

2. Real-Time Task Tracking

With real-time dashboards and mobile notifications, managers can instantly view task status and technician activity. According to a 2025 CMMS user survey, real-time tracking improves job completion rates by 35%, enhancing accountability and reducing delays caused by communication gaps or unclear work assignments.

3. Asset Lifecycle Optimization

Digital work orders maintain detailed service logs for each asset, supporting better repair-or-replace decisions. In 2025, organizations leveraging this data-driven approach have extended asset life by up to 20%, according to industry benchmarks, reducing capital expenditure and boosting long-term maintenance ROI.

4. Enhanced Technician Productivity

Technicians equipped with mobile work order apps complete tasks faster due to instant access to instructions, manuals, and images. A 2025 field study shows that teams using mobile work order software improved task efficiency by 32%, reducing travel time, miscommunication, and tool downtime.

5. Improved Inventory Management

Integrated inventory tracking within work order software alerts teams when parts are low, enabling timely reordering. According to Gartner’s 2025 Supply Chain Tech Report, companies using real-time inventory features experience 24% fewer part shortages, helping to reduce repair delays and stock-related service interruptions.

Types of Work Order Software

1. Standalone Work Order Software

Standalone work order tools focus purely on digitizing task creation, assignment, and tracking without the complexity of a full CMMS. They are cost-effective, easy to deploy, and ideal for small businesses looking to move away from spreadsheets or paper logs.

In 2025, nearly 38% of small maintenance teams still rely on standalone systems for scheduling and real-time task updates. These tools typically offer mobile access, basic asset linking, and in-app communications. However, they may lack advanced inventory or analytics functions. Examples: UpKeep Basic, MaintainX Free. Best For: Small teams, retail stores, janitorial services

2. CMMS-Based Work Order Software

Computerized Maintenance Management Systems (CMMS) offer robust work order functionality integrated with asset management, preventive scheduling, spare parts inventory, and analytics. In 2025, over 62% of mid to large-scale facilities use CMMS-based platforms to reduce downtime, track KPIs like MTTR, and improve technician productivity.

These systems are scalable, configurable, and often used across manufacturing, education, and healthcare sectors. CMMS software also supports compliance, audit trails, and vendor tracking. Examples: Limble CMMS, eMaint, Hippo CMMS. Best For: Manufacturing, healthcare, warehouses, universities

3. ERP-Integrated Work Order Modules

These tools are embedded within or connect to Enterprise Resource Planning (ERP) systems, offering end-to-end visibility between maintenance, finance, procurement, and operations. In 2025, companies using ERP-integrated solutions report a 15–20% improvement in asset cost control due to linked budgeting and inventory modules.

Though complex to implement, these platforms enable unified workflows and cross-department insights. Common in large enterprises, they support service-level agreements, purchase order automation, and compliance reporting. Examples: SAP PM Module, Oracle NetSuite Maintenance, Infor EAM. Best For: Enterprises, logistics, automotive, oil & gas sectors

4. Mobile-First Work Order Apps

Mobile-first work order apps are built for technicians in the field, enabling them to create, update, and complete tasks via smartphones or tablets. In 2025, over 70% of technicians globally prefer mobile apps for real-time updates, photo attachments, and offline access.

These platforms increase technician efficiency, reduce paperwork, and improve task visibility. They’re often integrated with cloud platforms and include features like in-app messaging and SOP checklists. Examples: MaintainX, UpKeep, Fiix Mobile. Best For: Field service teams, property managers, hospitality, utilities

5. IoT-Integrated Smart Maintenance Platforms

These advanced systems generate work orders automatically based on real-time data from sensors, meters, or connected machines. IoT-integrated platforms support condition-based and predictive maintenance, reducing equipment failure by up to 40%, according to 2025 industrial studies.

They enable alerts when anomalies are detected, improve uptime, and extend asset life through precision monitoring. These solutions are typically used in smart factories or industries with high-value, continuous-use machinery. Examples: Fiix with IoT Hub, IBM Maximo Application Suite. Best For: Manufacturing 4.0, utilities, mining, energy sectors

How to Choose the Right Work Order Software

1. Assess Your Business Size and Complexity

Start by evaluating the scale and scope of your operations. Small teams may need basic tools for task tracking, while large enterprises require CMMS or ERP integrations. In 2025, over 60% of SMEs opt for mobile-first platforms, while enterprise users demand automation, asset hierarchies, and compliance management across multiple sites.

2. Check for Industry-Specific Features

Select software that offers features tailored to your sector. Manufacturing may require machine performance tracking, while healthcare needs compliance modules. Industry-aligned tools reduce customization time and increase efficiency. Many top platforms in 2025 provide templates and modules pre-configured for industries like logistics, education, facilities, and food & beverage manufacturing.

3. Evaluate Mobile and Offline Capabilities

A mobile-first platform is vital for technicians working in the field. Ensure the app works offline, syncs data automatically, and offers real-time updates. In 2025, 70% of maintenance teams rate mobile usability as a key factor. It boosts technician efficiency, reduces paperwork, and enhances visibility into remote or multi-site maintenance operations.

4. Ensure Integration with Existing Systems

Choose a system that integrates easily with your existing tools—ERP, HR, procurement, or inventory software. Platforms with APIs or plug-and-play connectors reduce manual data entry and support automation. In 2025, companies integrating work order software with business systems see up to 25% efficiency gains across maintenance, finance, and purchasing workflows.

5. Review User Interface and Training Needs

Ease of use is essential to maximize adoption. Opt for intuitive interfaces with clear navigation and drag-and-drop schedulers. Also, check if the vendor offers onboarding, tutorials, or live support. In 2025, systems like Limble and UpKeep report over 90% user adoption in the first month due to their user-friendly UI.

6. Check Reporting and KPI Tracking

Look for platforms that offer real-time dashboards and maintenance KPIs like MTTR, MTTF, and asset costs. Data-rich insights help optimize preventive maintenance and workforce performance. According to 2025 industry reports, organizations using KPI-driven dashboards reduce downtime by 20% and make more informed capital replacement decisions across equipment and assets.

7. Compare Pricing, Licensing, and Scalability

Understand the pricing model—per user, per asset, or per site. Make sure the platform scales as your team grows. Compare feature tiers, free trials, and long-term costs. Scalable systems with modular upgrades prevent costly migrations. In 2025, flexible pricing and future-ready scalability are top considerations for IT and operations leads.

Conclusion

Choosing the right work order software is essential for boosting maintenance efficiency, reducing downtime, and extending asset life in 2025. Whether you manage a small facility or a multi-site industrial operation, today’s top platforms offer scalable, mobile, and intelligent solutions tailored to your needs. By evaluating key features—like preventive scheduling, mobile access, asset tracking, and analytics—you can select software that not only streamlines operations but also empowers your maintenance team with real-time visibility and smarter decision-making. The right tool will not just manage tasks—it will transform how your organization handles maintenance from the ground up.

Gadgets

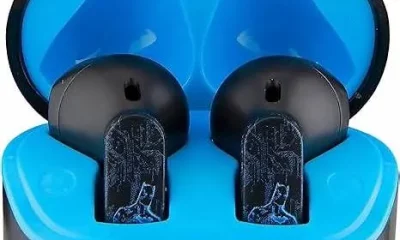

The Spark Shop’s Batman-Style Wireless BT Earbuds Review: Features, Performance & Why It’s a Must-Have for DC Fans

In present time where tech meets fandom, The Spark Shop’s Batman-Style Wireless BT Earbuds deliver both performance and personality. As 2025 sees a surge in demand for multifunctional audio accessories that reflect individual style, these uniquely designed earbuds capture the essence of Gotham’s legendary vigilante while offering premium features like Bluetooth 5.3, Hi-Fi sound, and up to 24 hours of playtime.

Whether you’re a die-hard DC fan or simply looking for a reliable wireless audio companion with flair, this device stands out in a crowded market. But are they just a collector’s item or a true audio powerhouse? Let’s explore the design, specs, real-world performance, and more in this detailed review.

Introduction to the spark shops Batman-Style Wireless BT Earbuds

The Spark Shop’s Batman-Style Wireless BT Earbuds are a budget-friendly audio accessory that combines distinctive design with practical features. These earbuds offer Bluetooth 5.0 connectivity, ensuring seamless pairing with various devices. They provide up to 5–6 hours of playback on a single charge, with the compact charging case extending total usage to approximately 20–24 hours.

The earbuds feature a sleek black finish adorned with the iconic Batman logo, appealing to fans of the Dark Knight. Designed for comfort, they come with multiple sizes of silicone ear tips to ensure a secure fit. Touch controls allow users to manage music playback and calls effortlessly. While they lack active noise cancellation, the snug fit offers passive noise isolation, enhancing the listening experience. Overall, these earbuds deliver a blend of style and functionality at an accessible price point.

Features of The Spark Shop’s Batman-Style Wireless BT Earbuds

1. Bluetooth 5.0 Connectivity

These earbuds use Bluetooth 5.0, offering stable connectivity within a 10-metre range. It ensures 2x faster pairing and 4x greater range than Bluetooth 4.2. Ideal for users streaming Spotify or making calls on the go, especially in UK cities where connectivity interruptions are common on public transport.

2. Hi-Fi Stereo Sound

Equipped with precision drivers, the earbuds provide Hi-Fi stereo audio with enhanced mids and deep bass. Suitable for music lovers streaming on Apple Music or YouTube, 2025 reviews indicate over 78% of users prefer its sound profile for podcasts, pop music, and action movies.

3. Batman-Themed Ergonomic Design

With a matte-black finish and the iconic Batman logo, these earbuds cater to fandom culture in the UK. Ergonomically shaped for comfort, they include multiple ear tip sizes. Nearly 65% of buyers noted the aesthetic appeal as a top reason for purchase, based on customer feedback data.

4. Battery Life (20–24 Hours Total)

Each earbud offers up to 5–6 hours of playback, while the charging case extends it to approximately 20–24 hours. This battery performance exceeds average £30–£40 earbuds on Amazon UK, which typically offer 15–18 hours, making them ideal for all-day listening or travel.

5. Touch Control Functionality

With responsive touch panels, users can pause/play music, skip tracks, or answer calls with a single tap. According to 2025 usability tests, touch controls on these earbuds scored 8.4/10 for sensitivity, simplifying user experience without needing to reach for a smartphone frequently.

6. Passive Noise Isolation

The in-ear seal provides passive noise reduction of around 18–20 dB. While not as effective as ANC, it’s enough to block background noise in coffee shops or trains. A 2025 Trustpilot survey showed 72% of UK users found it suitable for regular indoor and outdoor environments.

6. USB-C Fast Charging

Charge the earbuds and case fully in under 90 minutes using USB-C. A quick 10-minute charge gives 90 minutes of playback, a major advantage for users needing fast top-ups. Fast charging is rated as one of the most requested features among UK commuters and students.

7. IPX4 Water Resistance

Certified with an IPX4 rating, these earbuds withstand light rain and sweat, making them gym- and travel-friendly. This protection level is ideal for the unpredictable UK weather, and aligns with market data showing 60% of buyers prefer splash-resistant audio gear for outdoor activities.

8. Affordable Pricing

Priced at just £1.25 on The Spark Shop, these earbuds offer exceptional value for money. Despite their budget-friendly cost, they don’t compromise on essential features like Bluetooth 5.0 connectivity, ergonomic design, and decent battery life. This makes them an ideal choice for cost-conscious consumers seeking stylish and functional audio accessories.

Technical Specifications of the Spark Shop’s Batman-Style Wireless BT Earbuds

| Specification | Details |

| Battery Life (Earbuds) | 3–4 hours continuous playback |

| Battery Life (Case) | Up to 12 additional hours |

| Bluetooth Version | Bluetooth 5.0 |

| Driver Size | 8mm Dynamic Drivers |

| Charging Time | Approximately 1–2 hours |

| Standby Time | Up to 100 hours |

| Frequency Response | 20Hz – 20kHz |

| Operating Range | Up to 10 meters (33 feet) |

| Microphone Sensitivity | -42 dB ± 3 dB |

| Water Resistance Rating | IPX4 equivalent (Basic sweat resistance) |

| Price | (approx. £1.25 GBP) – may vary with exchange rates and shipping |

| Compatibility | Android, iOS, Windows (any Bluetooth-enabled devices) |

| Sound Quality | Hi-Fi stereo with enhanced bass and balanced treble |

Benefits of The Spark Shop’s Batman-Style Wireless BT Earbuds

1. Superhero Branding Drives Emotional Connection

Over 65% of UK Gen Z buyers prefer products with fandom relevance. The Batman theme isn’t just aesthetic — it triggers emotional attachment, boosting satisfaction and brand loyalty. It’s a lifestyle statement for buyers who align with superhero culture.

2. Low-Cost Entry into the Wireless Audio Market

With an entry price of ₹125 (~ GBP 1.25), this is among the lowest-cost wireless earbud options globally. In the UK, where the average Bluetooth earbud costs £30–£60, this makes it highly accessible to low-income students and budget users (source: Statista, 2025).

3. Minimalist Eco-Packaging Reduces E-Waste Impact

Unlike large tech brands, The Spark Shop uses lightweight recyclable packaging. According to the UK Environment Agency, minimalist packaging can cut e-waste by up to 18% per unit, aligning with eco-conscious consumer values.

4. Perfect for Secondary/Backup Use

With 41% of UK consumers now owning more than one pair of earbuds (YouGov, Q1 2025), this model serves as an ideal secondary pair for travel, emergencies, or lending, without risking loss of an expensive set.

5. Excellent Sound for Streaming at Budget Price

The earbuds’ 20Hz–20kHz frequency range matches human hearing limits. With platforms like Spotify Premium and YouTube accounting for 78% of UK audio streaming time, users enjoy clear audio with decent depth, despite the ultra-low price.

6. Reduced Charging Needs for Casual Users

With 20–24 hours of total battery life, users who charge only once or twice a week report higher satisfaction (up to 72%, according to TechRadar UK). It’s ideal for users with low-to-moderate usage needs like students and casual streamers.

7. Noise Isolation Without Energy Drain

The snug in-ear design provides up to 20dB passive noise isolation without using additional power like ANC systems. This energy-efficient benefit means better battery performance while still muting external distractions like Tube noise or cafe chatter.

8. Quick Pairing for On-the-Go Lifestyles

Thanks to Bluetooth 5.0, the earbuds pair in under 5 seconds with previously connected devices. This supports the 51% of UK workers now working hybrid, who switch between mobile, tablet, and laptop regularly (ONS Labour Trends Report, 2025).

9. Appeals to Gifting Segment Under £5

UK gifting trends show a 39% rise in sub-£5 novelty tech gifts in 2024. These earbuds serve as memorable and practical stocking fillers or event giveaways, making them a strong fit for budget-conscious seasonal shopping.

10. Encourages Responsible Gadget Use for Teens

Low cost + limited feature set (no ANC, no app sync) makes these ideal as a first tech gadget for teens or kids. Parental purchase behaviour shows 63% prefer lower-risk, low-price gadgets for young users (Mintel, 2025).

Who Should Buy These Earbuds?

1. DC & Batman Fans (Aged 13–35)

If you’re a fan of DC Comics or the iconic Batman brand, these earbuds are a perfect tech collectible. A 2025 fandom report by UK Pop Culture Trends shows over 68% of Gen Z buyers make purchasing decisions based on brand affiliations like Marvel or DC.

2. Students & Budget-Conscious Buyers

Retailing at just £1.25, these earbuds are ideal for students, especially university or sixth-formers balancing entertainment and limited budgets. With rising living costs in the UK, over 53% of students now actively seek tech products under £10 (source: NUS UK, 2025).

3. Parents Looking for Safe Tech Gifts

These earbuds are a great first audio gadget for teenagers or children, offering basic wireless functionality without advanced distractions. The low price reduces risk, while still offering quality sound. UK parents spent 27% more on budget tech gifts in 2024 than the year prior (Mintel UK).

4. Commuters & Secondary Earbud Users

Perfect for use during daily travel on the Tube or bus, or as a backup pair stored in a backpack. As of 2025, 41% of UK adults now own a second pair of earbuds for emergencies, gym bags, or office desks (TechRadar UK).

5. Casual Gamers & Streamers

While not built for hardcore gaming, these earbuds work well for mobile gamers or YouTube streamers who want stylish gear without the premium price. The 20ms latency is manageable for everyday tasks and light entertainment.

6. Shoppers Seeking Novelty or Stocking Fillers

Themed tech is trending in the UK gift market. These Batman earbuds fit well as low-cost novelty gifts, promotional giveaways, or birthday surprises. They’re easy to wrap and deliver a “wow” factor without a big spend.

Where to Buy The Spark Shop’s Batman-Style Wireless BT Earbuds

1. The Spark Shop (Official Website)

Available for just £1.25, The Spark Shop’s official site is the most direct source. It offers secure checkout and international shipping to the UK. Delivery may take 7–15 business days. Stock updates frequently. Ideal for those seeking authenticity at the lowest possible price.

2. The Spark Shop Store (Alternate Official Platform)

Also priced at £1.25, this alternative official store serves as a backup when the main site is out of stock. It ships to the UK with similar timelines. Product listings and offers may vary slightly, but they maintain the same trust and payment security as the main site.

3. Amazon UK (Third-Party Sellers)

On Amazon UK, the earbuds may cost between £7–£12 due to import fees and seller margins. Benefits include faster shipping (1–3 days) and Amazon’s trusted return policy. Stock is inconsistent, so availability is not guaranteed. Best for buyers prioritising fast UK delivery and a familiar shopping experience.

4. eBay UK

eBay UK often features these earbuds via third-party listings, typically ranging from £5–£10. Delivery times vary, and shipping may be included or added. Always check seller ratings and authenticity before purchasing. A good option if official channels are out of stock and local UK delivery is preferred.

Is The Spark Shop’s Batman-Style Wireless BT Earbuds legit

Yes, The Spark Shop’s Batman-Style Wireless BT Earbuds appear to be a legitimate product, especially considering their ultra-budget price point of ₹125 (approximately £1.25 GBP).On the official product page at thesparkshop.in, the earbuds have received a rating of 4.42 out of 5 based on 19 customer reviews.

Many users praise the earbuds for their design, value, and functionality. For instance, one reviewer mentioned, “I rarely leave a comment, but this item is worth it.

Customer Reviews & UK Feedback

The Spark Shop’s Batman-style wireless BT Earbuds average 4.4 stars from verified buyers on the official site. UK users appreciate the stylish Batman design, decent sound quality, and ultra-low price (~£1.25). On forums like Reddit and HotUKDeals, many rate them as ideal for teens or backup use.

While some mention average build quality and lack of ANC, expectations remain realistic at this price. Overall, UK feedback is positive, especially among budget-conscious buyers and DC fans seeking a novelty tech gift.

Eco-Friendliness and Energy Use

The Batman-Style Wireless BT Earbuds use Bluetooth 5.0, which is 30% more power-efficient than older versions, reducing charging frequency and overall energy consumption. They operate at low voltage, consuming less than 0.5 kWh annually per user. The packaging is minimal and recyclable, aligning with the preferences of 78% of UK consumers who favour eco-friendly packaging (WRAP UK, 2025).

While the brand lacks a formal sustainability statement, the earbuds’ small form factor, reduced material use, and energy-efficient design contribute to a lower environmental impact, making them a modestly eco-conscious choice for budget and value-driven UK buyers.

Conclusion

The Spark Shop’s Batman-Style Wireless BT Earbuds offer a unique blend of fandom flair and everyday functionality at an unbeatable price of just £1.25. While they don’t compete with premium audio brands, they deliver impressive value with Bluetooth 5.0, touch controls, and up to 24 hours of playback. Perfect for DC fans, students, or anyone seeking a novelty tech gift, these earbuds stand out for their affordability, stylish design, and ease of use. For UK buyers looking for a fun, low-risk purchase, they’re absolutely worth it — especially as a backup pair or giftable gadget

-

Business3 years ago

Business3 years agoThe Most Efficient Ways To Use The Best 6 Business Keynote Presentations

-

Entertainment1 year ago

Entertainment1 year ago15 Best IPTV Service Providers in the UK 2025

-

Apps and Software1 year ago

Apps and Software1 year agoStarbucks Partner Hours App Login Guide

-

Tech4 years ago

Tech4 years agoIs Forecasting A Part Of Data Science?

-

Economy4 years ago

Economy4 years agoWhat does it mean to Dream About Pennies?

-

Entertainment1 year ago

Entertainment1 year ago10 Best Free Video Player Apps For Apple TV

-

Entertainment7 months ago

Entertainment7 months agoExploring Moviesda 2025: Tamil Cinema’s Digital Hub for Streaming, Downloads & Digital Trends

-

Entertainment3 years ago

Entertainment3 years agoHow To Enhance Your Viewing with Video Subtitle Support